EP-D04

ELECTRICAL EQUIPMENT LOCKOUTS

Electrical equipment lockouts are safety procedures designed to protect personnel from accidental energization, electric shock, or other hazards during maintenance, repair, or inspection of electrical systems. These protocols ensure that equipment is completely de-energized and remains in a safe state until work is completed.

Key Components of Electrical Equipment Lockouts:

- Energy Isolation:

- Identify and isolate all energy sources (e.g., circuit breakers, fuses, disconnect switches) to prevent power from reaching the equipment.

- Use physical locks and tags to secure isolation devices, ensuring they cannot be reactivated without authorization.

- Tagging:

- Attach a clearly labeled tag to the lockout device, indicating the reason for the lockout, the date, and the authorized personnel responsible.

- Testing:

- Verify that the equipment is de-energized using voltage testers or multimeters before work begins.

- Authorization:

- Only trained and authorized personnel may apply or remove locks.

- Communication:

- Coordinate lockout procedures with all affected personnel to avoid misunderstandings or accidents.

- Record-Keeping:

- Maintain logs of lockout activities, including dates, equipment involved, and personnel involved.

Regulatory Compliance:

- Adhere to standards such as OSHA 1910.147 (Lockout/Tagout) in the U.S., or equivalent global regulations (e.g., IEC 60204-1 for machinery safety).

Purpose:

To eliminate the risk of injury or death by ensuring electrical equipment is safely shut down and cannot be inadvertently restarted during servicing.

To eliminate the risk of injury or death by ensuring electrical equipment is safely shut down and cannot be inadvertently restarted during servicing.

- Product Description

- Specification Parameters

- Product Features

- Related Products

Product Description

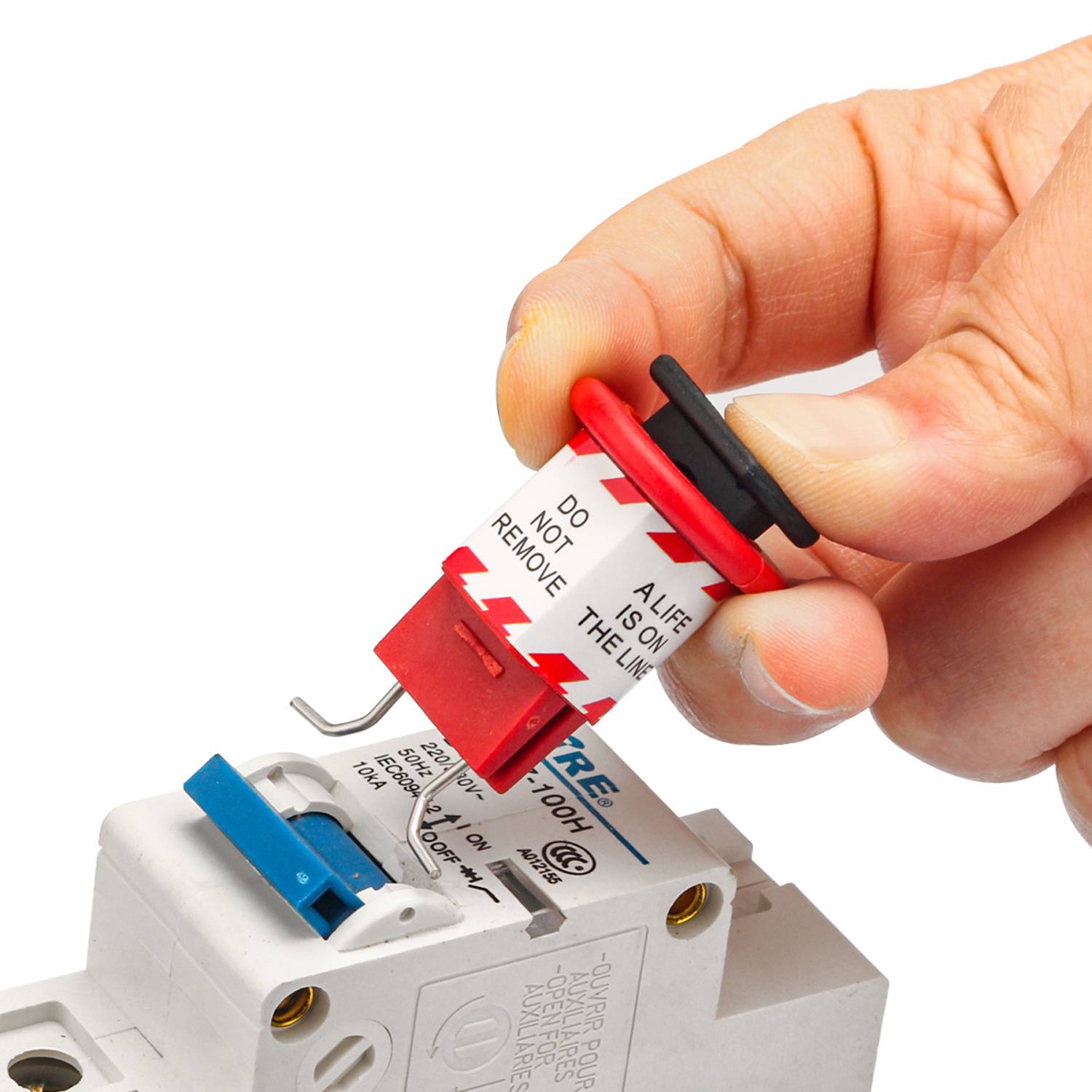

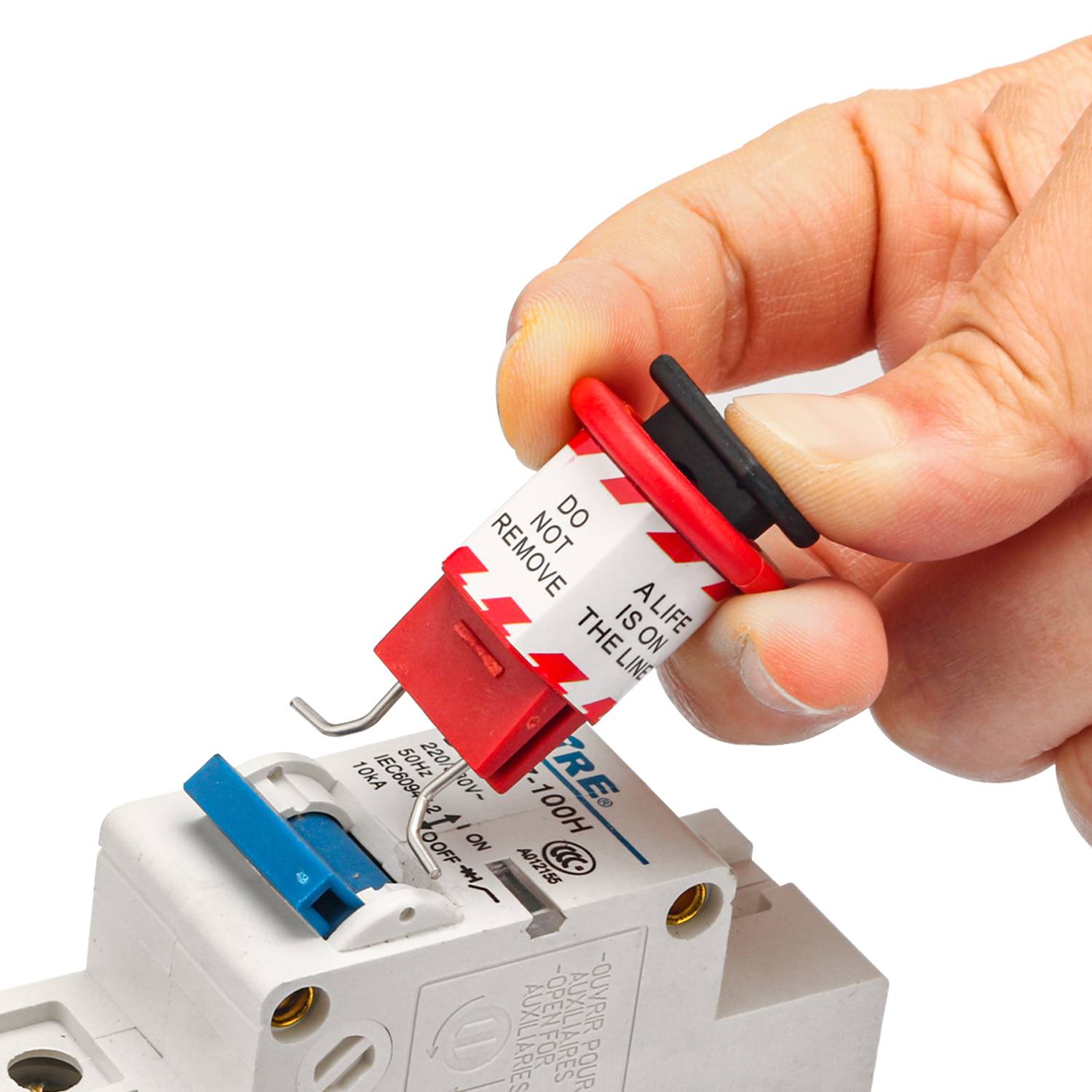

Miniature Circuit Breaker Lockout

Crafted from glass - filled nylon, a high - performance material renowned for its exceptional durability, impact resistance, and chemical stability, this lockout ensures long - lasting reliability in diverse electrical environments. It is recommended for use in combination with a padlock (shackle diameter up to 6 mm) to enhance safety, preventing unauthorized activation of circuit breakers. The intuitive push - button installation allows for quick and effortless setup, eliminating the need for complex procedures or additional tools.

This lockout boasts several key features:

- OEM Manufacturing Service Supported: Tailor - made solutions to meet specific business requirements, ensuring seamless integration with existing systems.

- No Installation Tools Required: Enables immediate use, saving time and effort in critical situations.

- Suitable for Single and Multi - Pole Breakers: Offers versatility across a wide range of electrical configurations, from simple to complex setups.

Designed to fit most existing European and Asian circuit breakers, it guarantees broad compatibility. The model lineup includes:

- EP - D01: POS (Pin Out Standard) with hole spacing ≤12mm, ideal for standard - configuration breakers.

- EP - D02: POS (Pin In Standard) with hole spacing ≤12mm, suitable for inward - pin setups.

- EP - D03: TBLO (Tie Bar Lockout), engineered for specialized tie - bar applications.

- EP - D04: POW (Pin Out Wide) with hole spacing ≤20mm, designed for wider - spaced breaker configurations.

Specification Parameters

|  MINIATURE CIRCUIT BREAKER LOCKOUT |  MINIATURE CIRCUIT BREAKER LOCKOUT |

|---|---|---|

| In-Stock Key Code Availability | No | No |

| Max # of Key Codes | - | - |

| Custom Engraving Options | Yes | Yes |

| Key Retaining | NO | NO |

| Body Color Options | Red | Red |

| Electrical Protection | Nylon | Nylon |

Download

Download