Industrial Manufacturing

1. Core Applications

- Energy Isolation:

- Secure electrical circuit breakers, hydraulic pumps, pneumatic valves, and conveyor belts to eliminate risks of unexpected motion, voltage, or pressure release.

- Common in machinery like CNC machines, presses, robotics, and assembly lines.

- Critical Equipment:

- Lockout of motor controls, guards, and feed systems during routine maintenance or tool changes.

- Isolation of boilers, compressors, and chemical storage tanks to prevent hazardous material leaks.

Core Elements of a Lockout Solution

-

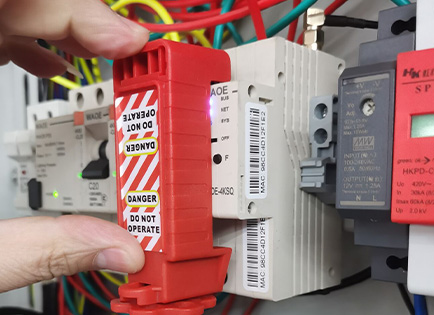

Circuit breaker lockouts

>Circuit breaker lockouts – isolate high-voltage panels -

Valve lockouts

>Valve lockouts – control pneumatic and hydraulic systems -

Plug lockouts & cable lockouts

>Plug lockouts & cable lockouts – for non-standard or large plugs -

Custom lockout stations

>Custom lockout stations – centralize your lockout program -

Heavy-duty padlocks

>Heavy-duty padlocks – designed for durability in harsh environments

Steps for Implementing a Lockout Solution (LOTO Procedure)

-

Preparation

Identify all energy sources connected to the machinery or system that requires servicing.

-

Shutdown

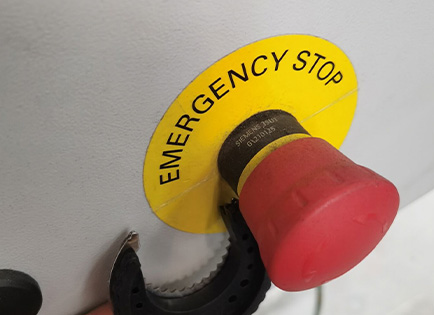

Power down the equipment following the proper shutdown procedure for the specific machine or system.

-

Isolation

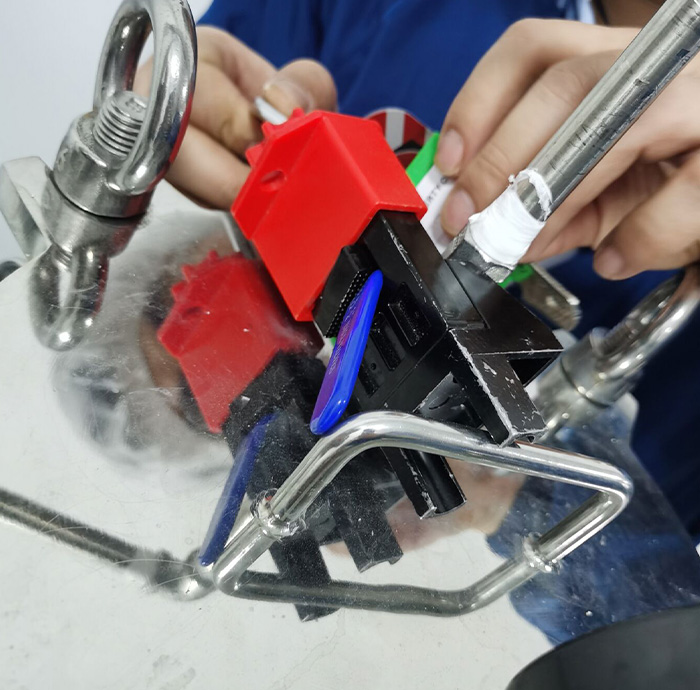

Physically isolate the machine or equipment from all its energy sources (electrical, mechanical, hydraulic, etc.) using the appropriate lockout devices (e.g., padlocks, valve lockouts).

-

Lockout

Apply lockout devices to all energy-isolating points. Each worker involved in the maintenance should apply their own lock, ensuring multiple levels of protection.

-

Tagout

Attach tags to all locked-out devices, providing clear information about who is responsible for the lockout and the purpose.

-

Release Stored Energy

Safely release any stored energy (e.g., hydraulic pressure, residual electrical energy) in the system to prevent accidental activation.

-

Verification

Verify that the lockout was successful by attempting to operate the machine’s controls to ensure it cannot be energized.

-

Maintenance/Servicing

Perform the required maintenance or servicing while ensuring the lockout remains in place.

-

Re-energizing the Equipment

After the work is completed, verify that all tools and workers are clear from the area. Remove locks in reverse order, with each worker removing their lock only when their part of the work is complete.

-

Restart

Restore energy to the equipment and test it to ensure proper functionality.

CUSTOMER CASES

Industry-Specific Lockout Solutions

Different industries may require specialized lockout devices and procedures due to their specific operational risks. Common examples include:

Industry-Specific Lockout Solutions

Different industries may require specialized lockout devices and procedures due to their specific operational risks. Common examples include:

Industry-Specific Lockout Solutions

Different industries may require specialized lockout devices and procedures due to their specific operational risks. Common examples include:

CUSTOMER REVIEWS

What travelers community are saying.

A***e

⭐ ⭐ ⭐ ⭐ ⭐

I really enjoyed interacting with the supplier. Everything went smoothly and professionally. The products were dispatched and received on time and the quality is impeccable. I would recommend this supplier as they are truly professional and friendly. I didn't experience any problem and I appreciate this smooth transaction.

U***e

⭐ ⭐ ⭐ ⭐ ⭐

Good Quality products. I will order from them again. Good customer service.

J***o

⭐ ⭐ ⭐ ⭐ ⭐

The products they make are of great quality, the customer service is excellent, and everyone is very professional.

K***y

⭐ ⭐ ⭐ ⭐ ⭐

conforme à ma description. je suis très satisfait et recommande vos produits et services

Lockout Solution FAQ

-

What is Lockout/Tagout (LOTO)?

-Lockout/Tagout is a safety procedure used to ensure machines are completely shut off and cannot be restarted before maintenance or repair work is completed. It involves isolating energy sources and placing locks and tags to prevent accidental start-up.

-

Why is LOTO important in industrial manufacturing?

+In industrial environments, machinery often involves multiple energy sources (electrical, mechanical, hydraulic, pneumatic, etc.). LOTO prevents serious injuries or fatalities by ensuring these energies are fully controlled during servicing.

-

Who is responsible for performing LOTO?

+Only authorized employees—those trained and approved to perform lockout/tagout—can apply or remove lockout devices. Affected employees (e.g., machine operators) must understand the purpose but cannot perform lockout themselves.

-

What are common energy sources in manufacturing?

+1. Electrical power

2. Hydraulic pressure

3. Compressed air (pneumatic)

4. Stored mechanical energy (springs, flywheels)

5. Thermal energy (heat or steam)

6. Chemical energy (hazardous substances) -

What types of equipment require lockout?

+Conveyor systems

Press machines

Injection molding equipment

CNC machines

Packaging equipment

Mixers, blenders, and rotating equipment

Electrical panels and control cabinets -

How often must LOTO procedures be reviewed?

+Annually. OSHA and most global safety standards require a yearly audit of LOTO procedures to ensure compliance and effectiveness.

-

What should be included in a LOTO program?

+A written LOTO policy

Machine-specific procedures

Proper lockout/tagout devices

Employee training

Regular audits and inspections

Documentation and record-keeping -

Can multiple employees lock out the same equipment?

+Yes. This is called a group lockout. Each worker applies their personal lock to a group lockout device (like a hasp or group lock box). The equipment cannot be re-energized until every lock is removed.