EP-D03

- Energy Isolation:

- Identify and isolate all energy sources (e.g., circuit breakers, fuses, disconnect switches) to prevent power from reaching the equipment.

- Use physical locks and tags to secure isolation devices, ensuring they cannot be reactivated without authorization.

- Tagging:

- Attach a clearly labeled tag to the lockout device, indicating the reason for the lockout, the date, and the authorized personnel responsible.

- Testing:

- Verify that the equipment is de-energized using voltage testers or multimeters before work begins.

- Authorization:

- Only trained and authorized personnel may apply or remove locks.

- Communication:

- Coordinate lockout procedures with all affected personnel to avoid misunderstandings or accidents.

- Record-Keeping:

- Maintain logs of lockout activities, including dates, equipment involved, and personnel involved.

- Adhere to standards such as OSHA 1910.147 (Lockout/Tagout) in the U.S., or equivalent global regulations (e.g., IEC 60204-1 for machinery safety).

To eliminate the risk of injury or death by ensuring electrical equipment is safely shut down and cannot be inadvertently restarted during servicing.

- Product Description

- Specification Parameters

- Product Features

- Related Products

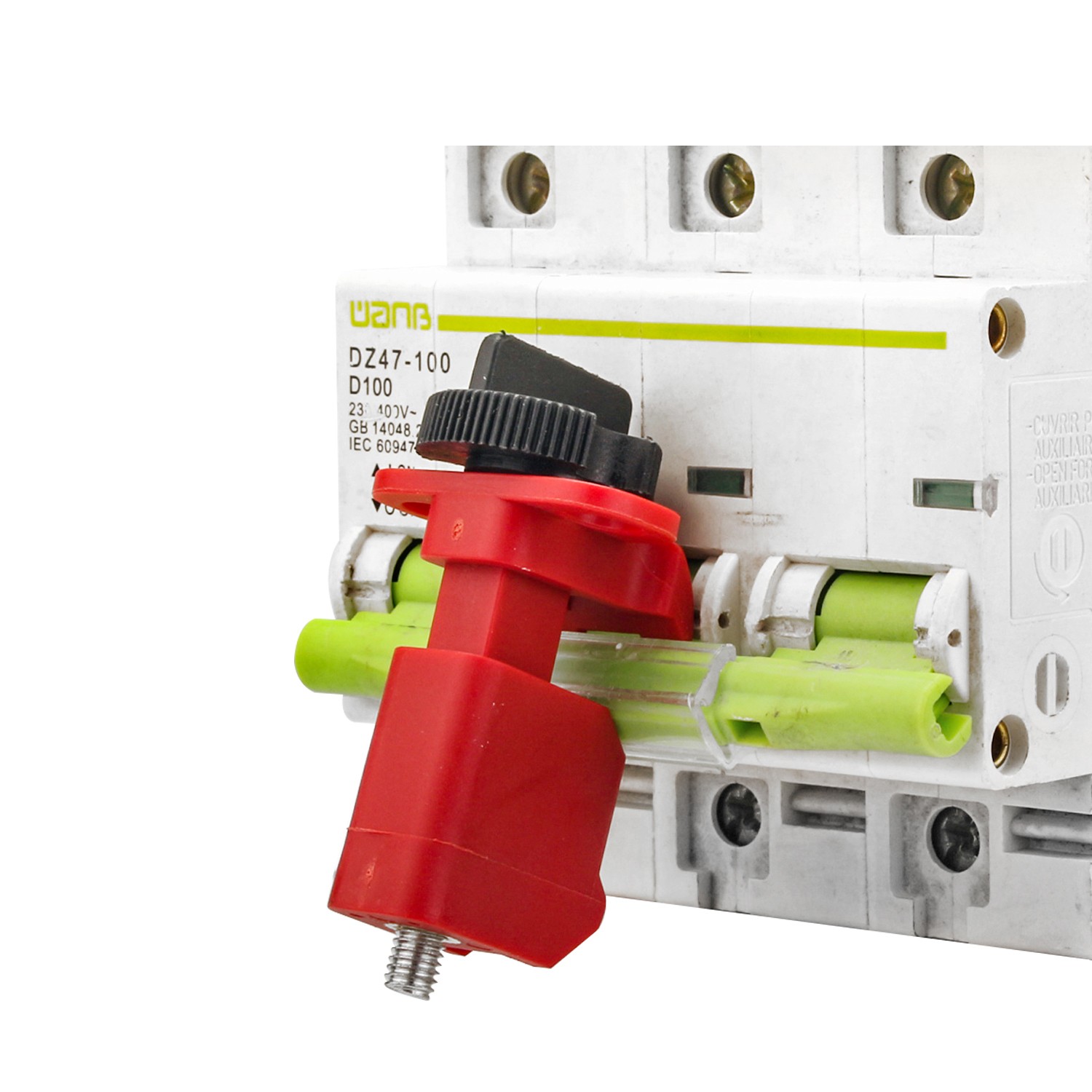

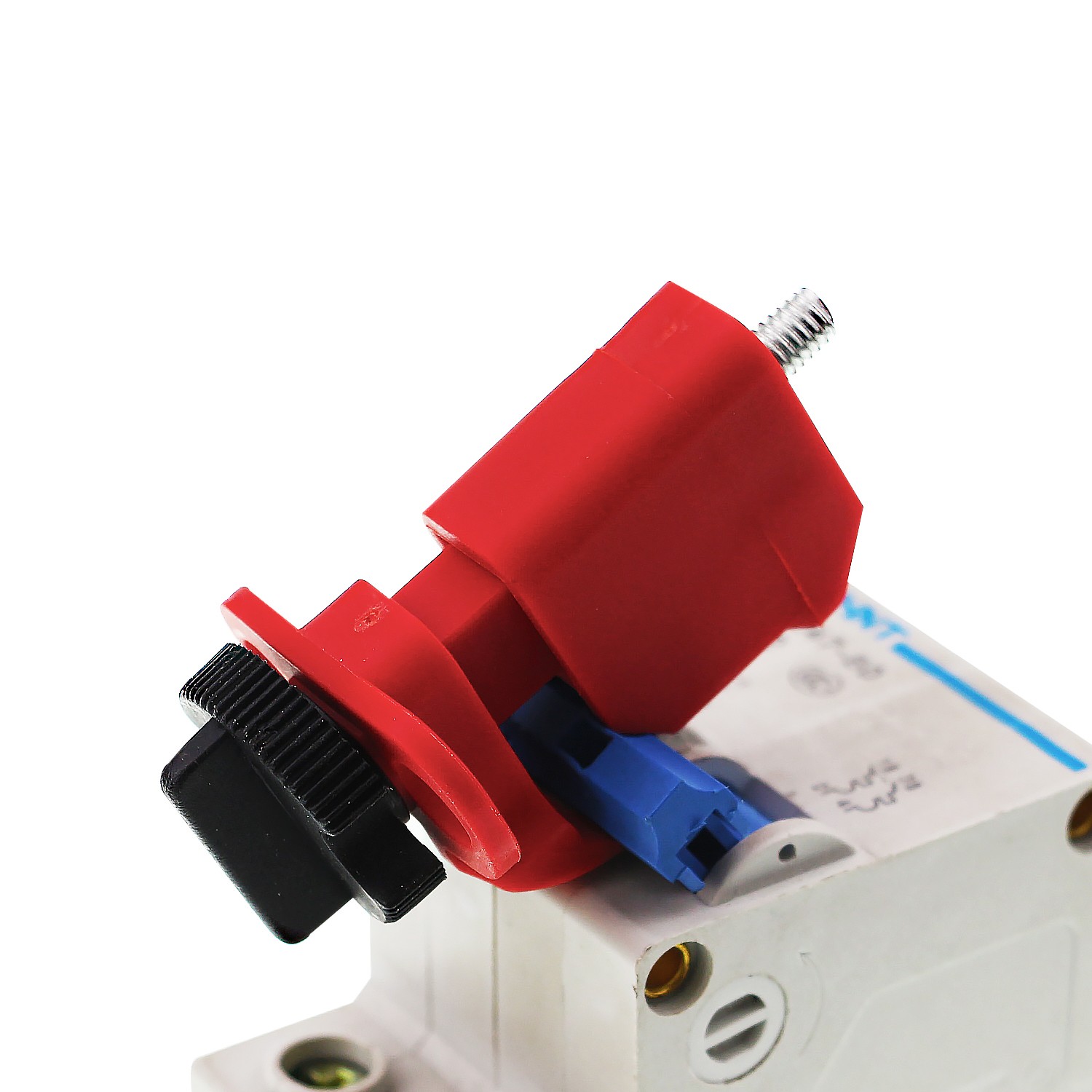

Product Description

- OEM Manufacturing Service Supported: Tailor - made solutions to meet specific business requirements, ensuring seamless integration with existing systems.

- No Installation Tools Required: Enables immediate use, saving time and effort in critical situations.

- Suitable for Single and Multi - Pole Breakers: Offers versatility across a wide range of electrical configurations, from simple to complex setups.

- EP - D01: POS (Pin Out Standard) with hole spacing ≤12mm, ideal for standard - configuration breakers.

- EP - D02: POS (Pin In Standard) with hole spacing ≤12mm, suitable for inward - pin setups.

- EP - D03: TBLO (Tie Bar Lockout), engineered for specialized tie - bar applications.

- EP - D04: POW (Pin Out Wide) with hole spacing ≤20mm, designed for wider - spaced breaker configurations.

Specification Parameters

|  MINIATURE CIRCUIT BREAKER LOCKOUT |  MINIATURE CIRCUIT BREAKER LOCKOUT |

|---|---|---|

| In-Stock Key Code Availability | No | No |

| Max # of Key Codes | - | - |

| Custom Engraving Options | Yes | Yes |

| Key Retaining | NO | NO |

| Body Color Options | Red | Red |

| Electrical Protection | Nylon | Nylon |

Product Features

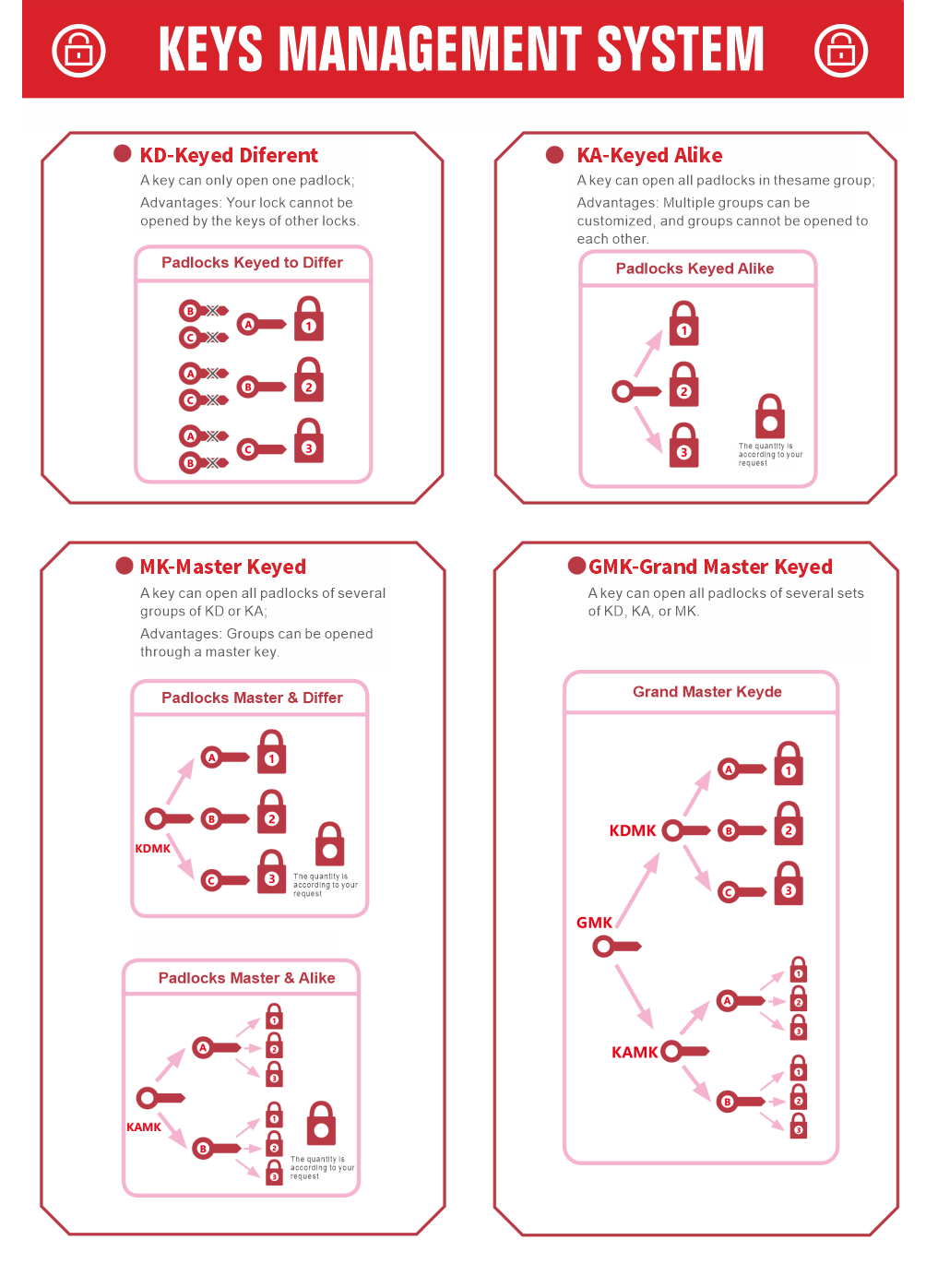

Key management system:

KD (Keyed to Differ): This means each lock has its own unique key. No two locks in a "KD" system will open with the same key

KA (Keyed Alike): In this system, multiple locks are designed to be opened by the same key. This is useful for situations where one key needs to unlock several locks

MK (Master Key): A master key system allows one key (the "master key") to open multiple locks, while each lock also has its own individual key (often called a "subkey")

GMK (Gland Master Key): This is a specific term used in certain industries, usually related to locks that control access to particular areas or equipment. The gland master key would be part of a hierarchical system of access, potentially allowing the user to unlock specialized locks

Download

Download