Workplace safety is one of the most important responsibilities in industrial and commercial environments. Every day, workers operate heavy machinery, pipelines, and energy systems that require strict control. A major part of this control is energy isolation, which ensures that equipment is properly shut down and cannot release energy while being serviced. To achieve this, valve lockout devices play a central role in lockout tagout (LOTO) programs. They help protect workers, improve compliance, and prevent costly accidents.

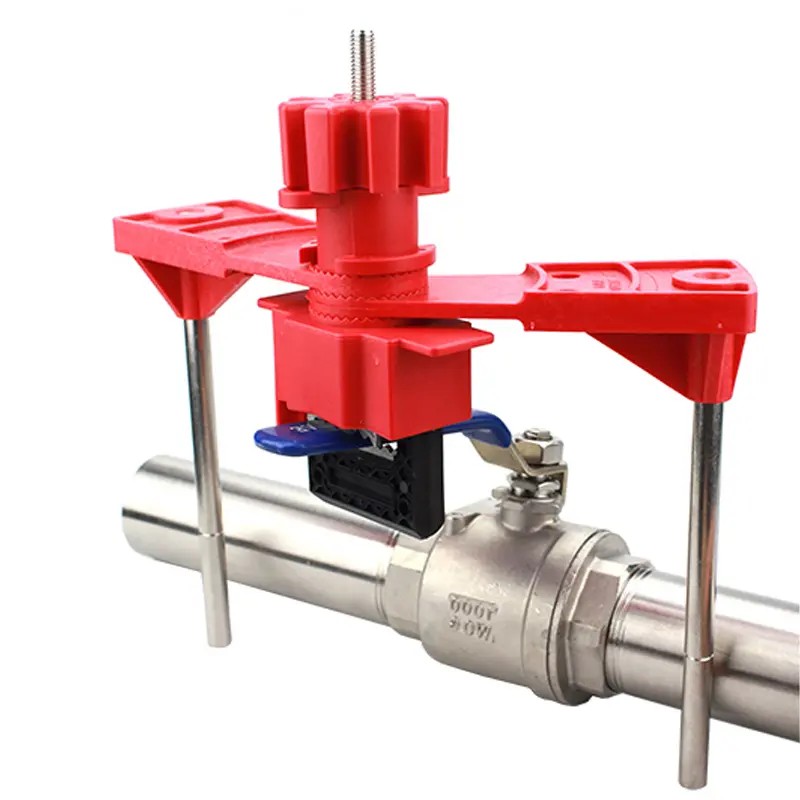

To understand their importance, it is first necessary to know what valve lockouts are. Valve lockout devices are safety tools designed to stop valves, switches, or control mechanisms from being operated while maintenance or repairs are underway. They physically secure the valve handle or wheel, making it impossible to turn until the lock is removed by authorized personnel. Many valve lockouts are brightly colored or labeled, which allows workers to quickly identify that a valve is locked out. By preventing unauthorized or accidental operation, these devices reduce the risks associated with hazardous energy release.

Because industries use many different types of valves, there are several kinds of lockout devices designed to meet specific needs. Ball valve lockouts cover the lever handles of ball valves to keep them in the off position. Butterfly valve lockouts secure the lever of butterfly valves, preventing movement. Gate valve lockouts fit over the round handwheel of gate valves to immobilize it completely. In more specialized environments, needle valve lockouts are used for small, high-pressure valves. For workplaces that handle multiple types of equipment, universal valve lockouts offer flexibility because they can be adjusted to fit a wide range of valve types and sizes. This variety ensures that every valve can be safely controlled during maintenance.

Now that the types are clear, it is important to see how they contribute to energy isolation. When machines or pipelines are shut down, they often store dangerous forms of energy such as electricity, steam, pressure, or chemicals. If a valve is accidentally opened, this energy can be released suddenly, leading to serious accidents. By applying a valve lockout device, companies can be sure that valves remain in a safe position until work is complete. This step is also a requirement of OSHA LOTO regulations and similar safety standards worldwide, which mandate proper lockout tagout procedures to protect employees.

The benefits of valve lockout devices go beyond simple control. First, they provide enhanced safety by preventing accidents caused by accidental valve operation. Second, they support regulatory compliance, which helps companies avoid penalties and maintain safe working environments. Third, valve lockouts are highly versatile and can be used across many industries and valve types. Another benefit is cost efficiency—while accidents can cause downtime, medical expenses, and equipment damage, lockouts are a low-cost measure that reduces these risks. Finally, their visual identification features, such as bright colors or warning labels, make them easy for workers to recognize, improving communication and overall workplace safety.

The use of valve lockouts is not limited to one field. In oil and gas, they are applied to pipelines and pumps to prevent hazardous leaks. In chemical processing plants, lockouts keep valves closed during maintenance, protecting workers from dangerous substances. Utilities and water treatment facilities rely on valve lockouts to secure pumps and control valves, ensuring safe operations. In manufacturing plants, valve lockouts protect employees performing routine servicing on machinery. They are also used on construction sites for heavy equipment, preventing accidental activation. This wide range of applications shows just how valuable valve lockouts are in ensuring consistent workplace safety.

To maximize the benefits of valve lockouts, industries should follow some best practices. The first step is to choose the right type of lockout device for each valve in the facility. Next, companies must create a standardized lockout tagout procedure that clearly outlines when and how to apply these devices. Employee training is another crucial element, since workers need to know how to properly use lockouts and identify when they are in place. Finally, businesses should conduct regular inspections of lockout devices to ensure they remain effective, replacing worn or damaged units when needed. These practices strengthen LOTO programs and ensure reliable energy isolation.

In summary, valve lockout devices are vital tools for protecting workers and maintaining operational safety. They ensure effective energy isolation, reduce the risk of accidental energy release, and help companies comply with important safety regulations. Their versatility, cost-effectiveness, and clear visibility make them an essential part of any lockout tagout program. By adopting valve lockouts, businesses demonstrate a strong commitment to both safety and efficiency.

If your organization is looking for reliable solutions, ELECPOPULAR SAFETY is a trusted valve lockout supplier offering high-quality lockout tagout devices to meet industrial needs. Partner with us to enhance workplace safety and protect your team with proven LOTO solutions.