In modern industrial systems, butterfly valve lockouts play a vital role in controlling the flow of liquids and gases. Known for their simple design and efficient operation, butterfly valves are widely used across various sectors, from water treatment to oil and gas. Understanding their structure, benefits, and applications is essential for engineers, maintenance personnel, and procurement teams.

This article explores what butterfly valves are, how they work, their key components, advantages, and where they are most commonly applied. Additionally, it highlights the importance of safety measures such as butterfly lockout devices during maintenance procedures.

A butterfly valve is a type of flow control device that allows for quick shut-off or regulation of fluid flow. It operates through a quarter-turn rotational mechanism — a 90-degree turn of the handle either fully opens or completely closes the valve.

The core element of a butterfly valve is a disc mounted on a rotating shaft. When the valve is closed, the disc blocks the passage entirely. When open, the disc rotates parallel to the flow, allowing unrestricted movement of the media through the pipe.

These valves are especially popular in large-diameter piping systems due to their compact size and lightweight construction.

Butterfly valves consist of four primary components:

Valve Body

The body serves as the main housing and connects the valve to the pipeline. Common designs include wafer-type (sandwiched between two flanges) and lug-type (secured with bolts through the valve’s outer casing).

Disc

Also known as the butterfly plate, the disc controls the flow by rotating within the valve. Its shape and orientation can be optimized for improved sealing and reduced flow resistance.

Stem

The stem connects the actuator to the disc. It may be a one-piece or split-stem design. In resilient-seated models, the stem is often isolated from the media to allow for cost-effective material selection.

Seat

The seat provides a seal between the disc and the valve body when closed. It is typically made from elastomers, polymers, or metal, depending on the application. Some seats are bonded to the body, while others are pressed or locked in place.

Butterfly valves offer several distinct advantages that make them a preferred choice in many industrial settings:

Compact Design

Due to their slim profile, butterfly valves require less space than other types of valves, making them ideal for installations with limited room.

Cost-Effective

Their simple construction means fewer materials are needed, resulting in lower manufacturing and purchasing costs. Wafer-type valves, in particular, are economical solutions for flanged pipeline systems.

Quick Operation

A single 90-degree turn is sufficient to fully open or close the valve. This rapid response makes them suitable for applications requiring frequent adjustments.

Low Maintenance Requirements

With fewer moving parts and minimal wear over time, butterfly valves tend to have longer service lives and require less frequent servicing.

Versatility

They can be used with a wide range of media, including water, gases, chemicals, and slurries, under varying pressure and temperature conditions.

Due to their efficiency and adaptability, butterfly valves are employed in numerous industries:

Water Treatment Plants

Used to regulate the flow of clean water, wastewater, and sewage in municipal and industrial water systems.

Chemical Processing Industry

Ideal for handling corrosive fluids and gases, provided the valve materials are compatible with the media.

HVAC Systems

Employed in heating, ventilation, and air conditioning systems to manage the flow of chilled water, steam, and hot water.

Food and Beverage Industry

Sanitary butterfly valves are used to transport food-grade liquids, ensuring hygiene and preventing contamination.

Oil and Gas Sector

Applied in pipelines for crude oil, refined fuels, and natural gas distribution, particularly in low-pressure environments.

High-Temperature and High-Pressure Systems

Double-offset and triple-offset butterfly valves are designed for extreme conditions, offering enhanced sealing performance.

While butterfly valves themselves are safe and reliable, proper precautions must be taken during maintenance or repair operations. Failure to isolate energy sources can lead to accidental release of pressurized media, posing serious risks to workers.

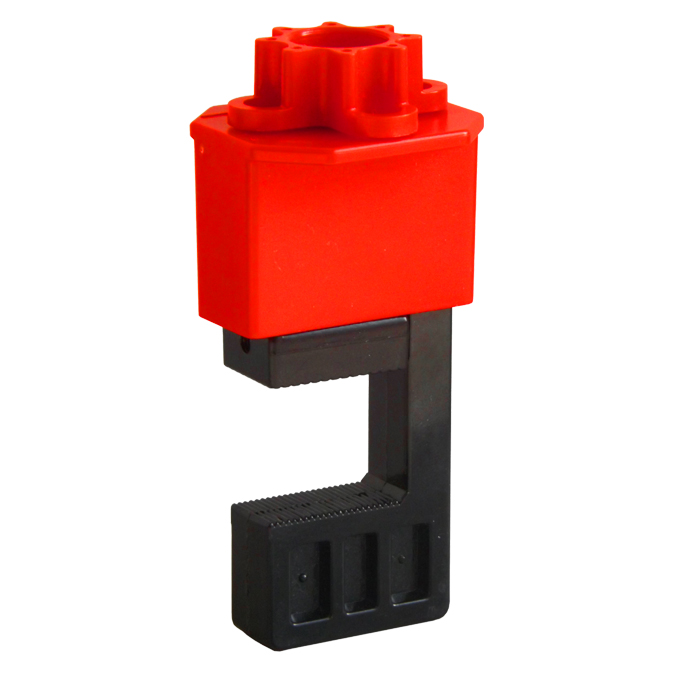

This is where butterfly lockout devices come into play. These tools are designed to secure the valve in a fixed position — usually closed — to prevent unintended operation. Key advantages of butterfly lockout devices include:

Ease of Installation

Most lockout devices are tool-free and can be quickly attached to the valve handle or lever.

High Visibility

Brightly colored designs ensure clear identification, even from a distance.

Durability

Constructed from high-quality materials such as nylon or stainless steel, these devices withstand harsh industrial environments.

Compatibility

Available in universal and specific designs, they fit a wide range of butterfly valve sizes and configurations.

Multi-Lock Capability

Many models feature multiple padlock points, allowing for group lockout procedures in compliance with LOTO standards.

Using butterfly lockout devices ensures compliance with OSHA regulations and enhances workplace safety during system maintenance.

Butterfly valves are essential components in modern industrial systems, offering a combination of efficiency, affordability, and reliability. Their straightforward design, consisting of just a few key parts, contributes to easy installation and long-term durability.

With applications spanning across water treatment, chemical processing, HVAC, and oil and gas industries, butterfly valves provide versatile flow control solutions. However, their use must be accompanied by appropriate safety protocols, particularly during maintenance.

Implementing butterfly lockout devices is a critical step in protecting workers and maintaining regulatory compliance. By understanding the components, advantages, and applications of butterfly valves, professionals can make informed decisions that enhance both operational efficiency and safety.