-

Land Drilling

Land drilling is the process of creating deep, vertical or directional boreholes in onshore geological formations to access subsurface resources, including oil, natural gas, groundwater, geothermal energy, or minerals. It is a critical component of the energy and mining industries, requiring specialized equipment, engineering precision, and adherence to safety and environmental standards.

View Details> -

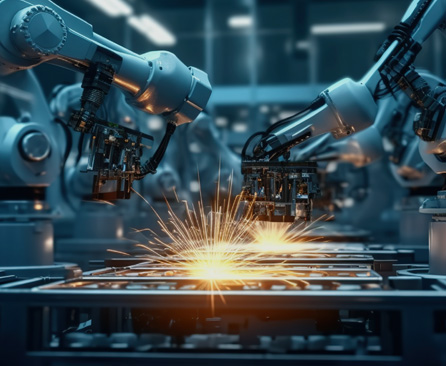

Industrial Manufacturing

In industrial manufacturing, safety padlocks are critical for enforcing Lockout/Tagout (LOTO)—a safety protocol to isolate hazardous energy sources (mechanical, electrical, hydraulic) during equipment maintenance, repairs, or setup. They prevent accidental machine startup, ensuring worker safety and compliance with global industrial standards.

View Details> -

Lockout Tagout In Automobile Industry

Lockout Tagout (LOTO) in the Automobile IndustryIn the automobile industry, Lockout Tagout (LOTO) is a critical safety practice designed to protect workers during equipment maintenance, repair, or setup by isolating hazardous energy sources. It involves securing machines and equipment with physical locks and warning tags to prevent accidental startup, ensuring no residual energy—electrical, mechanical, hydraulic, pneumatic, or thermal—can harm technicians.Compliant with global safety standards (

View Details> -

Power Transmission And Distribution

Core Elements of LOTO in T&D with Safety PadlocksA robust LOTO solution uses safety padlocks to physically isolate energy sources, ensuring compliance with standards like OSHA 1910.147, NFPA 70E, and IEC 60204-1.

View Details> -

Chemical Refining

In chemical refining, safety padlocks are critical for enforcing Lockout/Tagout (LOTO)—a safety protocol to isolate hazardous energy and material sources (chemical, mechanical, electrical) during maintenance, turnaround, or emergency shutdowns. They prevent accidental equipment activation, chemical leaks, or energy release in high-risk environments like refineries, petrochemical plants, and chemical processing units (CPUs).

View Details> -

Marine Oil

Marine Oil & Safety Padlock IntegrationIn marine oil operations, safety padlocks are critical for securing energy-isolating devices in offshore platforms, FPSOs (Floating Production Storage Offloading vessels), and subsea systems, aligning with Lockout/Tagout (LOTO) protocols to prevent accidental energization in harsh marine environments.

View Details>