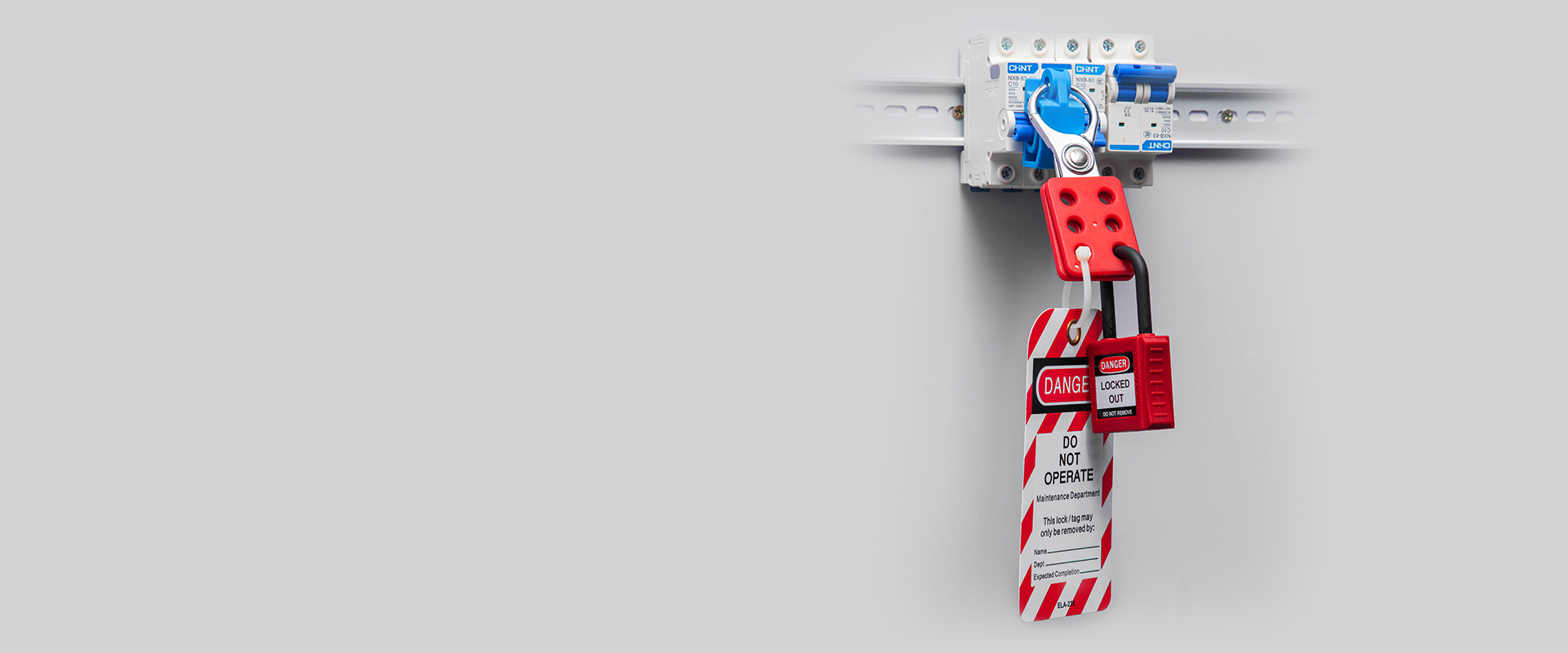

Lockout Hasps

-

EP-8311 1" Portable OEM lockout hasps

STEEL HASP LOCKOUTSteel hook with plastic coated body, 115mm lenth*45mm width, hook size is 25mm

Inquiry -

EP-8316 1" Lockout hasps for medium/small industrial equipment

Steel hook with plastic coated body, 115mm lenth*45mm width, hook size is 25mm

Inquiry -

EP-8326 1" Group lockout hasps in industrial maintenance

steel hook with plastic coated body,193mm length*45mm width, hook size is 25mm

Inquiry -

EP-8312 1.5" Reliable lockout hasps in repair environments

Steel hook with plastic coated body, 130mm lenth*60mm width, hook size is 38mm

Inquiry -

EP-8317 1.5" Steel hook with plastic coated body lockout hasps

Steel hook with plastic coated body, 130mm lenth*60mm width, hook size is 38mm

Inquiry -

EP-8327 1.5" Steel lockout hasps for collective safety

steel hook with plastic coated body,193mm length*60mm width, hook size is 38mm

Inquiry -

EP-8328 1" Safety lockout hasps for industrial lockout scenarios

steel hook with plastic coated body,193mm length*45mm width, hook size is 25mm

Inquiry -

EP-8329 1.5" User-friendly lockout hasps for large-scale equipment

steel hook with plastic coated body,193mm length*45mm width, hook size is 25mm

Inquiry -

EP-8311P High-quality steel lockout hasps for harsh conditions

Lock shackle 25mm(1”), 115mm lenthx40mm width

Inquiry -

EP-8320 Double-End robust construction lockout hasps

Allow to 6 padlocks, Hook Dia: Head dia: 44.5mm ;Tail dia: 18.5mm

Inquiry -

EP-8317P Long-lasting performance abrasion resistance lockout hasps

Lock shackle 38mm(1.5”) ,128mm lenthx40mm width

Inquiry -

EP-8316P Steel lockout hasp for industrial safety applications

Lock shackle 38mm(1.5”) ,128mm lenthx40mm width

Inquiry -

EP-8321 Customizable lockout hasps in lockout/tagout procedures

Size:18cm(H)x 7cm(W) Hole Dia:8.5mm Qty for padlock:9pcs

Inquiry -

EP-8322 Reusable write - on labels lockout hasps for flexibility

Size:17.8cm(H) x 7.3cm(W)Hole Dia:8.5mm Qty for padlock:5pcs

Inquiry -

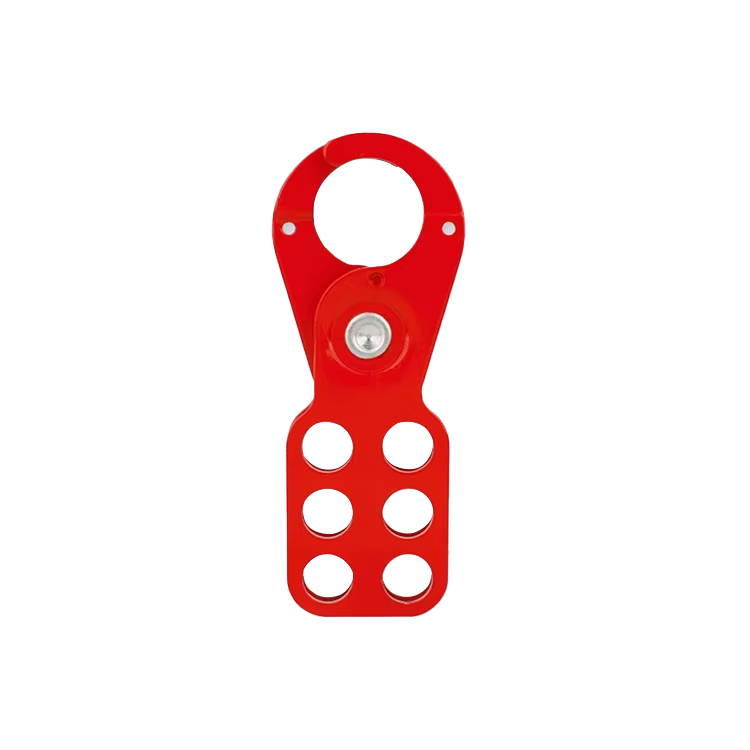

EP-8323 Integrated Design corrosion resistance lockout hasps

Size:11.6cm(H) x 5cm(W)Hole Dia:8.5mm Qty for padlock:6pcs

Inquiry -

EP-K71 Lightweight 12 padlocks lockout hasps

●Made from aluminum alloy●Lock hole diameter 8mm●Suitable for multi-person lock management

Inquiry -

EP-K72 24 padlocks aluminum buckle lockout hasps

●Made from aluminum alloy●Lock hole diameter 8mm●Suitable for multi-person lock management

Inquiry

PRODUCT ADVANTAGES

-

Perforated cable lock

Product model: EP- C15

Description: Lock single or multiple adjacent switches. After the key is pulled out, the steel cable can still be tightened infinitely, and multiple people can be locked at the same time. -

Circuit breaker lock

Model: EP-E26

Description: Mainly used for locking motor/motor circuit breaker switches

Features:

1. Made of reinforced nylon, strong and durable

2. Metal tooth clamping design, more stable locking

3. Loosen/tighten by hand, fast locking

4. Locking length: 41-57mm, width 38mm, height 22mm -

Button switch lock

Product model: EP-E39

Description: It can lock button switches with labels and various button switches at close range -

Plug valve lock

Model: EP-V42

Description: Mainly used for locking flanged ball valves/plug valves

Features:

1. Made of engineering plastics, light and tough

2. Simple structure and easy operation

3.8 hole design is easier to adjust and lock

4. Locking range: <DN150 -

Sanitary butterfly valve lock

Model: EP-V24

Description: Mainly used for locking sanitary butterfly valves

Features:

1. Made of engineering plastics, strong and durable

2. Patented package structure design, easy to lock and easy to operate

3. It can lock most of the existing sanitary butterfly valves

4. With 2 diameter 8mm and 1 diameter 6.5mm upper lock holes -

Multifunctional circuit breaker lock

Name: multifunctional circuit breaker lock

Model: EP-E15A

Description: It can not only lock the miniature molded case circuit breaker switch but also lock the miniature circuit breaker switch. -

Lockout tagout stations

Model No.: EP-X07

The Lockout tagout stations size:width × height × thickness: 360mm × 450mm × 155mm,With two mobile division plates, can set the division space flexibly. -

Lockout tagout kits

Lockout Tagout Kits includes:

Safety padlock *1 set

1 set of lockout box

1 set of miniature circuit breaker lockout

1 set of clamp breaker lockout

1 set of 6 holes lockout hasp

1 pcs Aluminum lockout hasp,plug lockout

1 set of emergency stop lockout

Safety Tag

FREQUENTLY ASKED QUESTIONS

-

1.What is a Lockout Hasp?

-A lockout hasp is a critical safety device designed to secure energy - isolating mechanisms during lockout/tagout (LOTO) procedures. It typically features a durable, adjustable body with multiple slots or holes that allow attaching multiple padlocks simultaneously—ideal for group lockout scenarios where multiple workers need to secure a single energy source. Constructed from materials like aluminum, steel, or non - conductive polymers, lockout hasps create a physical barrier to prevent unauthorized equipment operation. They fit over handles, switches, or valves, ensuring compliance with safety standards like OSHA 1910.147 by locking out machinery during maintenance, repair, or inspection.

-

2. What Are the Different Types of Lockout Hasps?

+Lockout hasps vary by design and material to suit specific industrial needs:

Standard Aluminum Hasps: Lightweight, corrosion - resistant, and suitable for general industrial use. Ideal for non - electrical environments where moderate strength is required.

Non - Conductive Hasps: Made from high - impact polypropylene or nylon, these eliminate electrical conductivity risks, making them essential for electrical panel lockout or applications near live circuits.

Heavy - Duty Steel Hasps: Built for harsh environments (e.g., chemical plants, offshore rigs), offering maximum durability and resistance to extreme temperatures, moisture, and mechanical stress.

Adjustable Jaw Hasps: Feature expandable/contractible jaws to fit irregularly shaped equipment, such as large valve handles or odd - sized switches, ensuring versatile compatibility. -

3. How Do I Choose the Right Lockout Hasp for My Application?

+Selecting the correct hasp involves assessing three key factors:

Environment & Hazards:

Use non - conductive hasps for electrical work to avoid shock risks.

Opt for stainless steel or coated hasps in wet, salty, or corrosive environments.

Equipment Compatibility:

Measure the diameter of handles/switches and check the hasp’s jaw opening width and slot spacing to ensure a secure fit.

For multi - worker lockouts, choose hasps with enough padlock slots (e.g., 2 - 10+ slots depending on team size).

Compliance Standards:

Verify certification to OSHA, ANSI, or ISO 45001 to ensure legal and safety compliance. -

4. Where Are Lockout Hasps Commonly Used?

+Lockout hasps are essential across industries to secure energy sources:

Manufacturing: On conveyor belts, presses, and assembly lines during maintenance.

Utilities: For circuit breakers, transformers, and electrical panels in power plants or substations.

Chemicals & Petrochemicals: On valves, pumps, and reactors to prevent accidental startup during shutdowns.

Construction: On heavy machinery (e.g., excavators, cranes) to lock out ignition switches or control panels.

Facilities Management: For HVAC systems, boilers, or water pumps during servicing. -

5. How Do I Install a Lockout Hasp?

+Installation follows these simple steps:

Isolate Energy: Turn off equipment and disconnect power/fluid sources per LOTO procedures.

Position the Hasp: Align the hasp over the target mechanism (e.g., a switch handle or valve wheel).

Secure the Hasp: Use the built - in clamp, screws, or straps to fasten it firmly to the equipment.

Add Padlocks: Insert each worker’s padlock through the hasp slots, ensuring all locks engage fully.

Tag the Hasp: Attach a lockout tag with the worker’s name, date, and reason for lockout. -

6. How Do I Maintain a Lockout Hasp?

+Regular maintenance ensures reliability and safety:

Inspect Monthly: Check for cracks, corrosion, or loose parts—replace damaged hasps immediately.

Clean Debris: Wipe down non - conductive hasps with a dry cloth; use mild detergent for metal hasps (avoid abrasive tools).

Lubricate Moving Parts: Apply silicone spray to adjustable jaws or sliding components to prevent sticking.

Store Properly: Keep hasps in dry, dust - free areas away from direct sunlight to extend material lifespan. -

7. Are Lockout Hasps OSHA - Compliant?

+Yes, when used correctly. OSHA’s LOTO standard (1910.147) requires that lockout devices:

Be standardized in color, shape, or size for easy identification.

Prevent accidental removal until all authorized workers remove their padlocks.

Have multiple lock slots for group lockouts.Always choose hasps labeled with OSHA - compliant or ANSI Z244.1 certification to meet regulatory requirements. -

8. Can Lockout Hasps Be Used with Other LOTO Devices?

+Absolutely—they complement other safety equipment:

Valve Lockouts: Use a hasp to secure a valve lock’s handle when multiple workers need access.

Circuit Breaker Locks: Attach a hasp to a breaker lock to accommodate team padlocks during shared lockouts.

Cable Lockouts: Combine with cable hasps for securing large - scale machinery with dispersed energy sources.This versatility makes them a core component of any comprehensive LOTO program. -

9. Where Can I Buy Lockout Hasps?

+Purchase from reputable industrial safety suppliers:

Online Retailers: Platforms like Grainger, SafetyGlobe, or Amazon offer wide selections with customer reviews.

Specialized Distributors: Companies like Brady, Master Lock, or Duralabel focus on LOTO solutions, ensuring certified products.

Direct from Manufacturers: For bulk orders or custom designs (e.g., branded hasps for enterprise fleets). -

10. How Much Do Lockout Hasps Cost?

+Prices range from

10to50+ depending on:

Material: Non - conductive or steel hasps are pricier than basic aluminum models.

Features: Hasps with more padlock slots (e.g., 6 - slot vs. 2 - slot) or adjustable jaws cost more.

Brand & Certification: Premium brands with OSHA/ANSI compliance may have higher price points. Buying in bulk often qualifies for discounts, making them cost - effective for industrial fleets.