WHAT IS A SECURITY PADLOCK

A safety padlock is a lock specifically designed for use in lockout/tagout (LOTO) procedures to prevent accidental operation of machinery or equipment during maintenance, repair, or cleaning.

-

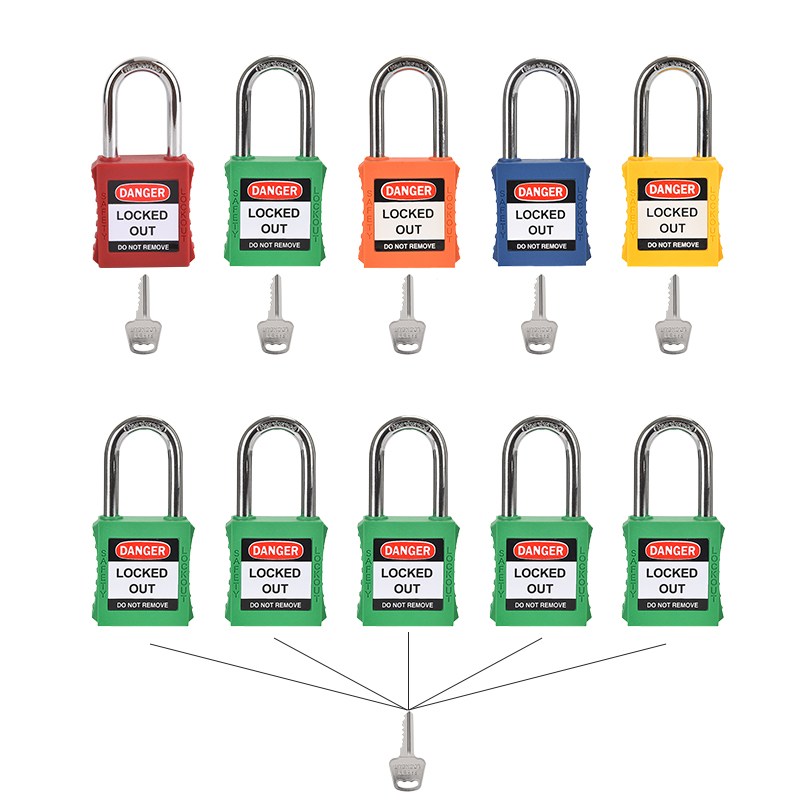

Lockout Padlocks

Lockout Tagout Padlocks and labels allow you to quickly id equipment, areas and padlocks with important lockout/tagout (LOTO) information. These are self-adhering high-performance labels that can withstand harsh environments, provide Master Key system and Grand Master Key system

Read More -

Lockout Hasps

Lockout hasps are a valuable and convenient way to lockout an energy source ensuring that your worker's safety is never compromised. Our hasps are available in a variety of highly visible, labeled and nonconductive options. They are ideal for group lockout procedures and will help give your team the piece of mind that each energy source is properly isolated.

Read More -

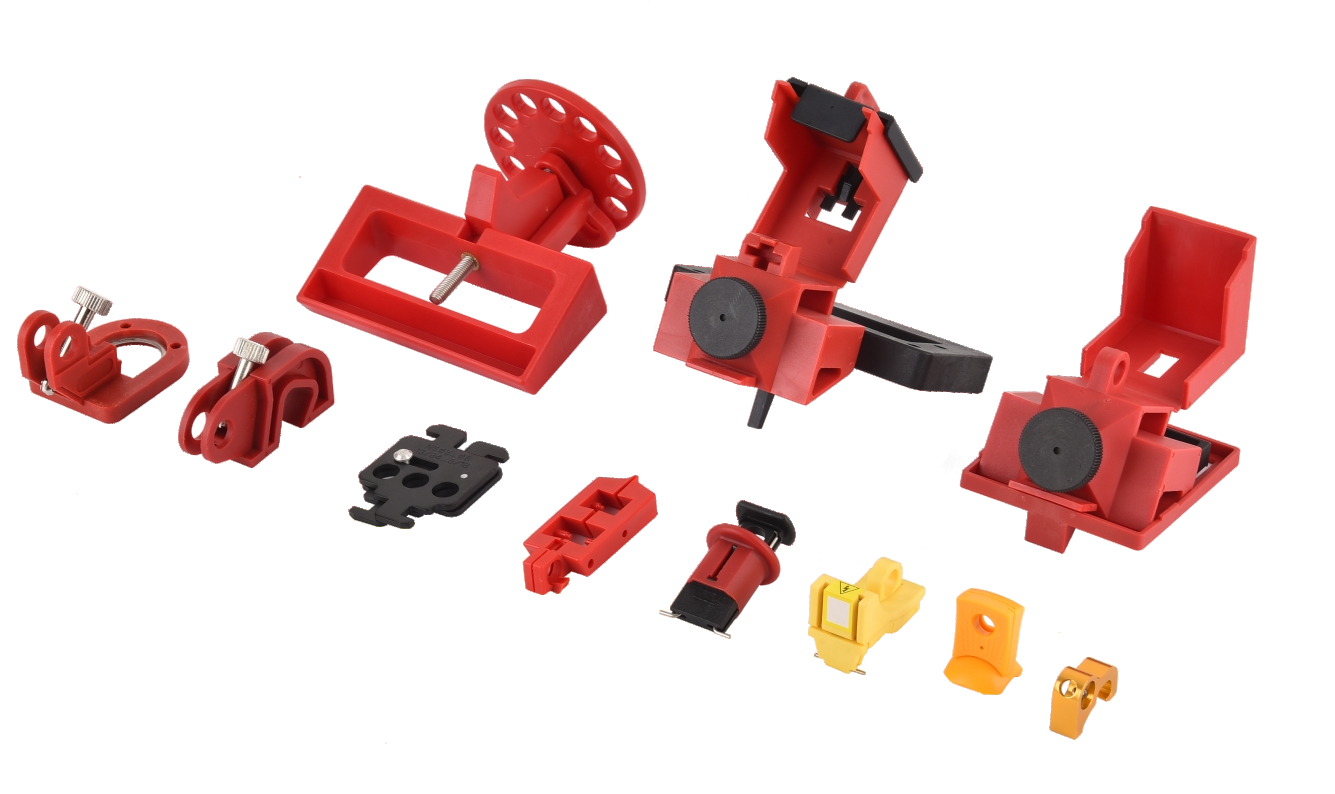

Electrical Equipment Lockouts

Our electrical lockout products will help you properly shut down electrical systems including: circuit breakers, push-buttons, rotary, wall switches, plugs and much more

Read More -

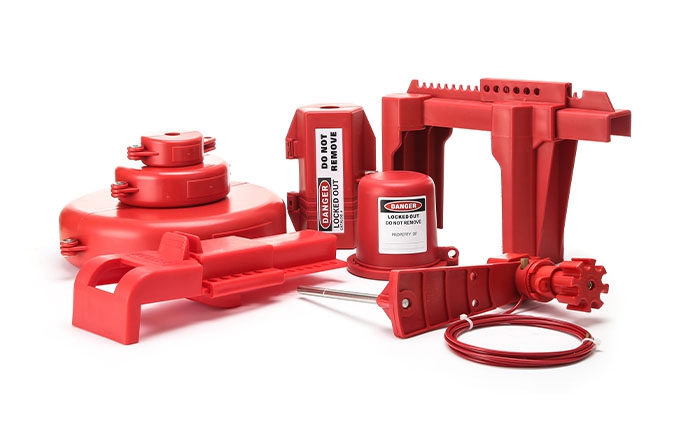

Valve Lockouts

Valve lockouts can be used for a wide variety of valve types, depending on the industrial application and the type of hazardous energy being controlled. Here are the most common types of valves that can be secured using valve lockouts, including ball valve, gate valve, plug valve, Butterfly Valves an so on

Read More -

Cable Lockouts

Our cable lockout devices are an easy-to-use multi-purpose energy isolation solution that is ideal for unusual devices that are difficult to lock using conventional means.

Read More -

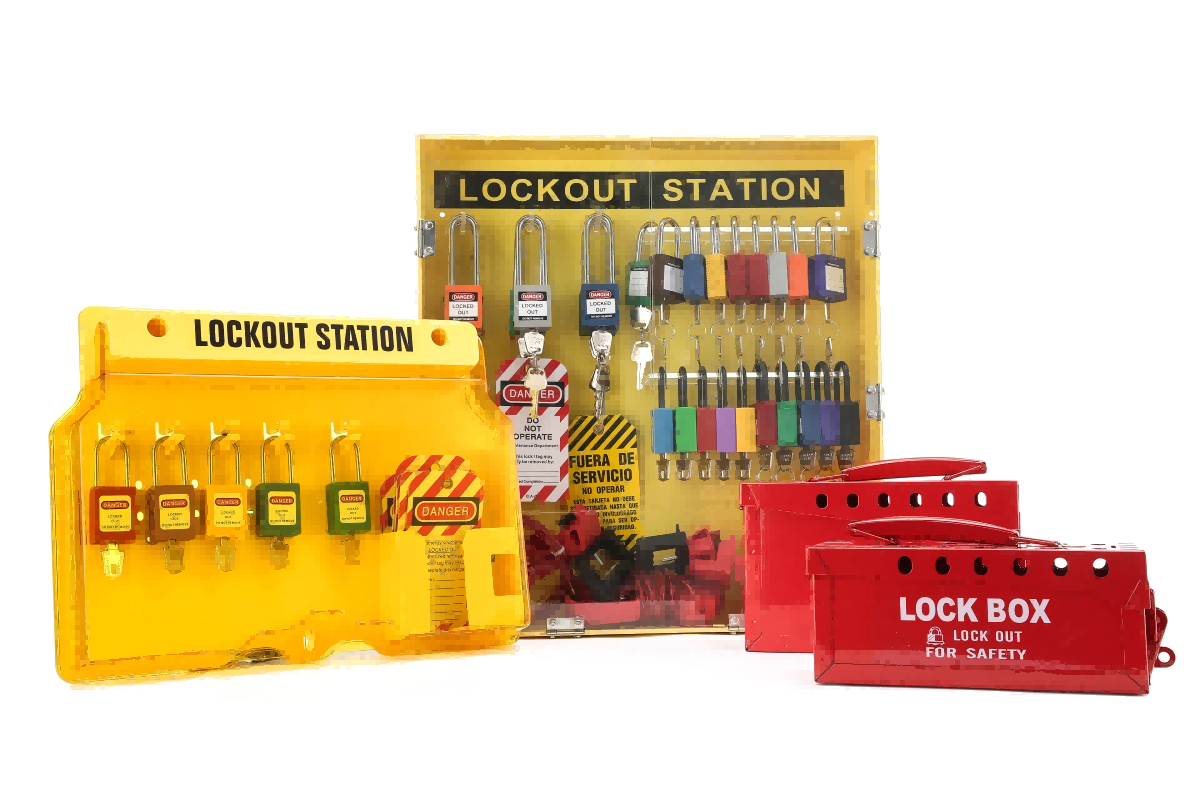

Lockout Tagout Stations

A Lockout/Tagout (LOTO) Station is an organized area or unit designed to store all the necessary lockout/tagout devices, tools, and supplies used to safely lock out equipment and machinery. These stations are typically used in industrial or manufacturing environments to make sure that workers have quick and easy access to all the LOTO devices they need for performing maintenance or repair tasks safely.

Read More -

Lockout Tagout Kits

Lockout/Tagout (LOTO) Kits are portable sets that contain the essential tools and devices needed for lockout/tagout procedures. These kits are designed for convenience, ensuring that workers have everything they need to safely isolate and secure energy sources during maintenance or repair tasks.

Read More -

Group Lockout Box

Group lockout boxes are a great solution for isolating energy points when a large team is working. Using a group lock box, and group lockout best practices, allows you to

Read More

LOCKOUT TAGOUT KITS

-

MATERIAL

Padlock Material. Choose from Zenex Thermoplastic, Aluminum, or Laminated Steel lock bodies.

Inquiry -

-

-

TYPES OF SAFETY PADLOCKS

ABS Safety Padlock/Metal Body Padlock/Lockout Hasps/Valve Lockout/Cable lockout/Lockout Kit&Box/Electrical Equipment Lockouts/Circuit Breaker Lockout/Pneumatic Lockout/Tagout &Scaffold Tags/Confined Space Cover/Lockout Station/Combination Lock/Emergency eye wash

-

Aluminum padlock

-

Nylon padlock

-

Steel Laminated padlockAluminum padlock

HOW TO CHOOSE YOUR PADLOCK

When choosing a safety padlock, several factors are essential to ensure it meets the necessary security, durability, and application-specific needs. Here's a guide to help you select the right safety padlock:

1. Meet OSHA Requirements

2. Choose the Lock Body Material

3. Select the Right Shackle

4. Decide on Key System

5. Use Color-Coding and Labels

6. Check for Environmental Resistance

1. Meet OSHA Requirements

-

OSHA (Occupational Safety and Health Administration) outlines 5 key requirements for safety padlocks:

·Durable: Resistant to heat, chemicals, and physical damage.

·Substantial: Strong enough to prevent removal without force or tools.

·Standardized: Consistent in color, shape, or size within your facility.

·Identifiable: Labeled with the employee’s name or ID.

·Exclusive: Only one key per employee (key-retaining design preferred).

2. Choose the Lock Body Material

| Material | Features | Use Case |

|---|---|---|

| Nylon | Lightweight, non-conductive, corrosion-resistant | Ideal for electrical or general use |

| Aluminum | Durable, lightweight, color-anodized | Mechanical or industrial settings |

| Steel | Strongest, high resistance to tampering | Harsh environments, not electrical |

| Thermoplastic | UV/chemical resistant, extreme temperature rated | Outdoor or chemical environments |

3. Select the Right Shackle

| Shackle Material | Features | When to Use |

|---|---|---|

| Nylon | Non-conductive, non-sparking | Electrical applications |

| Steel (chrome/hardened) | Tough and tamper-resistant | Mechanical equipment, heavy-duty |

| Stainless Steel | Rust- and corrosion-resistant | Outdoor or wet environments |

4. Decide on Key System

-

How to determine the key system

·Keyed Different (KD): One unique key per lock. Prevents accidental opening.

·Keyed Alike (KA): Multiple locks open with the same key (useful for one person).

·Master Keyed (MK): Each lock has a unique key, but one master key can open all (for supervisors).

·Key-Retaining: The key can't be removed unless the lock is closed – strongly recommended for safety use.

5. Use Color-Coding and Labels

Use Color-Coding and Labels:

·Use color-coded bodies (e.g., red for maintenance, blue for electrical, green for supervisor).

·Attach photo labels, engraved names, or warning tags for clear identification.

·Helps prevent lock removal by anyone other than the authorized employee.

6. Check for Environmental Resistance

If your facility involves:

·High temperatures

·Chemical exposure

·Wet or outdoor conditions

Choose locks specifically rated for these environments (e.g., thermoplastic or stainless-steel components).

SECURITY PADLOCK GUIDE

PRODUCT ADVANTAGES

-

Perforated cable lock

Product model: EP- C15

Description: Lock single or multiple adjacent switches. After the key is pulled out, the steel cable can still be tightened infinitely, and multiple people can be locked at the same time. -

Circuit breaker lock

Model: EP-E26

Description: Mainly used for locking motor/motor circuit breaker switches

Features:

1. Made of reinforced nylon, strong and durable

2. Metal tooth clamping design, more stable locking

3. Loosen/tighten by hand, fast locking

4. Locking length: 41-57mm, width 38mm, height 22mm -

Button switch lock

Product model: EP-E39

Description: It can lock button switches with labels and various button switches at close range -

Plug valve lock

Model: EP-V42

Description: Mainly used for locking flanged ball valves/plug valves

Features:

1. Made of engineering plastics, light and tough

2. Simple structure and easy operation

3.8 hole design is easier to adjust and lock

4. Locking range: <DN150 -

Sanitary butterfly valve lock

Model: EP-V24

Description: Mainly used for locking sanitary butterfly valves

Features:

1. Made of engineering plastics, strong and durable

2. Patented package structure design, easy to lock and easy to operate

3. It can lock most of the existing sanitary butterfly valves

4. With 2 diameter 8mm and 1 diameter 6.5mm upper lock holes -

Multifunctional circuit breaker lock

Name: multifunctional circuit breaker lock

Model: EP-E15A

Description: It can not only lock the miniature molded case circuit breaker switch but also lock the miniature circuit breaker switch. -

Lockout tagout stations

Model No.: EP-X07

The Lockout tagout stations size:width × height × thickness: 360mm × 450mm × 155mm,With two mobile division plates, can set the division space flexibly. -

Lockout tagout kits

Lockout Tagout Kits includes:

Safety padlock *1 set

1 set of lockout box

1 set of miniature circuit breaker lockout

1 set of clamp breaker lockout

1 set of 6 holes lockout hasp

1 pcs Aluminum lockout hasp,plug lockout

1 set of emergency stop lockout

Safety Tag

FREQUENTLY ASKED QUESTIONS

-

What is Lockout Tagout (LOTO)?

-LOTO is a safety procedure used to ensure that machines and equipment are properly shut off and not started up again before maintenance or servicing is completed.

-

Why is LOTO important?

+It protects workers from hazardous energy releases, accidental machine startups, and serious injuries or fatalities.

-

When should LOTO be used?

+LOTO must be used before servicing, maintenance, cleaning, or inspection of any machine or equipment that could unexpectedly start or release energy.

-

Who is authorized to perform LOTO?

+Only trained and authorized employees are allowed to apply and remove lockout/tagout devices.

-

What are the basic steps of a LOTO procedure?

+1. Prepare for shutdown

2. Notify affected employees

3. Shut down the equipment

4. Isolate energy sources

5. Apply lockout/tagout devices

6. Release stored energy

7. Verify isolation before work begins -

Can someone else remove my lock?

+No. Only the person who applied the lock can remove it. If they are unavailable, a specific removal procedure must be followed under supervision.

-

What types of energy are controlled by LOTO?

+LOTO equipment includes padlocks, lockout hasps, valve lockouts, circuit breaker lockouts, plug lockouts, tags, and lockout stations.

-

What equipment is used in a LOTO system?

+A safety padlock is a type of lock specifically designed to protect workers by preventing accidental operation of machinery or electrical circuits during maintenance or repairs. They are commonly used in lockout/tagout (LOTO) procedures to ensure a safe working environment.

-

Is training required for LOTO?

+Yes. Employees must be trained according to their role (authorized, affected, or other) to ensure proper understanding and compliance.

-

What are the consequences of not using LOTO?

+Failure to use LOTO can lead to severe injuries, fatalities, regulatory fines, and legal consequences for both the employee and the company.

Download

Download